Mahler

1. PM INDUSTRIE

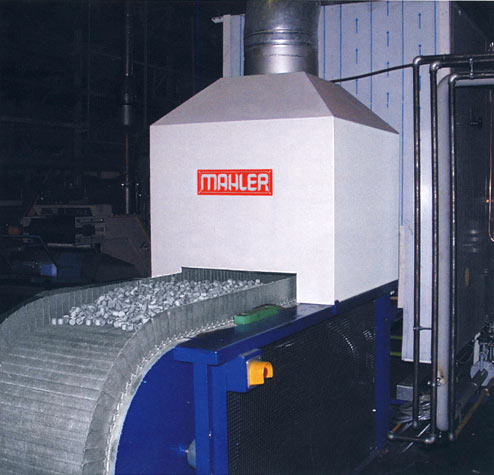

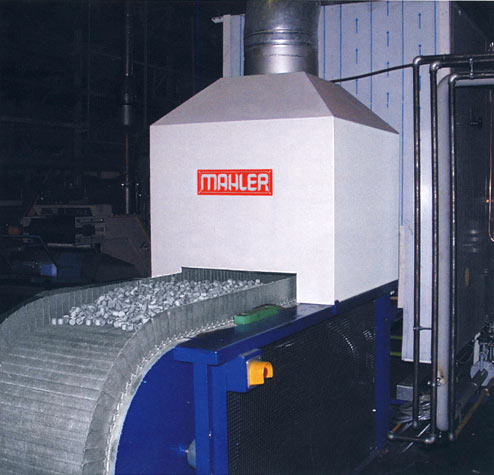

* Continuous furnaces

- Conveyor belt sintering furnaces

|

Characteristics |

- Working temperature up to 1150 °C

- Ceramic muffle in sintering zone

- Electrically heated or gas heated

- Operated with endogas and/or N2/H2 mixture

- Rapid dewaxing zone or dewaxing zone with muffle

- System extensions

|

|

Standard dimensions of sintering zone. Subject to technical alterations.

Belt width

(mm) |

length sintering zone

(mm) |

throughput capacity

(Netto Kg/h) |

furnace length

(m) |

300 |

3000 |

130 |

17 |

300 |

3750 |

160 |

18 |

300 |

4500 |

190 |

19 |

300 |

5250 |

220 |

20 |

450 |

4500 |

290 |

19 |

450 |

5250 |

330 |

20 |

600 |

5250 |

450 |

20 |

600 |

6000 |

520 |

21 |

600 |

7000 |

600 |

22 |

600 |

8000 |

700 |

23 |

1000 |

6000 |

830 |

21 |

|

|

|

- Separate furnace or a downstream tempering module

- Working temperatures up to 650 °C

- Electrically heated or gas heated

- Operated with protective gas or air

- With or without muffle

- With or without recirculation

- Cooling possible (to be used as cooling zone)

|

Picture: tempering module to temper PM components after hardening in a furnace cycle

- Aluminium sintering furnace

Characteristics

- Most accurate temperatures due to special distribution of temperature and protective atmosphere

- Dew point below -50 °C

- Various belt widths possible, e.g. 600 mm

- Long term production proved

- Heat treatment according to T1, T4 and T6

|

- High temperature sintering furnace Roller Hearth furnace

Temperatures 1200 °C – 1300 °C

100% Hydrogen or hydrogen/nitrogen mixtures

Advantages:

- Continuous with mesh belt

- Direct gas heated

- Oxide layer larger 4 microns

- High capacity

- Low energy consumption

|

|

You only need:

- Fuel gas for heating

- Softened water for integrated steam generation

- Electric current for driving unit and atmosphere cirulation

|

2. Brazing, annealing and gas-hardening furnaces

- Stainless steel applications

Characteristics

- Horizontal or humpback design

- Transport device with conveyor belt

- Heating - electric or with fuel gas

- Muffle in hot zone

- Protective gas: hydrogen and nitrogen atmosphere zoning

|

Continuous furnaces with protective gas atmosphere for heat treatment of machine components made of easily oxidised carbonised steel alloys (stainless steel, tool steel) and copper alloys (brass etc).

- Computer controlled and continuous documentation of the furnace parameters

- Automatic regulation and/or monitoring of the furnace atmosphere

- Automatic adjustment of the height of the loading and unloading doors in accordance with the height of the components

- Adaptation of the quantity of the protective gas (MAHLER patent)

- Gas quench device after the heating zone

- Convective cooling zone

- Automatic control of the gas flow

- Cooling water re-cooling system

Characteristics

- Transport device with conveyor belt or roller hearth

- Electric or with fuel gas

- No muffle in hot zone

- Protective gas provided through partial combustion of a fuel gas (natural gas, propane, LPG) or a nitrogen/hydrogen mixture inside the furnace. Requires no separate protective gas generator from 850 °C upwards!

- Saves energy through generation of protective gas inside the furnace

|

With protective atmosphere for heat treatment of machine components made of easily reducible steel and copper alloys.

- ACCESSORIES

- Computer control and continuous documentation of the furnace parameter

- Automatic regulation and/or monitoring of the furnace atmosphere

- Automatic adjustment of the loading and unloading doors according to height of parts

- Adaptation of quantity of protective gas (MAHLER patent)

- Gas quench device after heating zone

- Convective cooling zone

- Automatic regulation of gas flow

- Cooling water re-cooling system

- Gas hardening furnaces

For the manufacture of drills furnaces with gas quench are used. The drills are brazed and hardened in one furnace cycle at approx. 1120 °C. The protective atmosphere is a nitrogen/hydrogen mix.